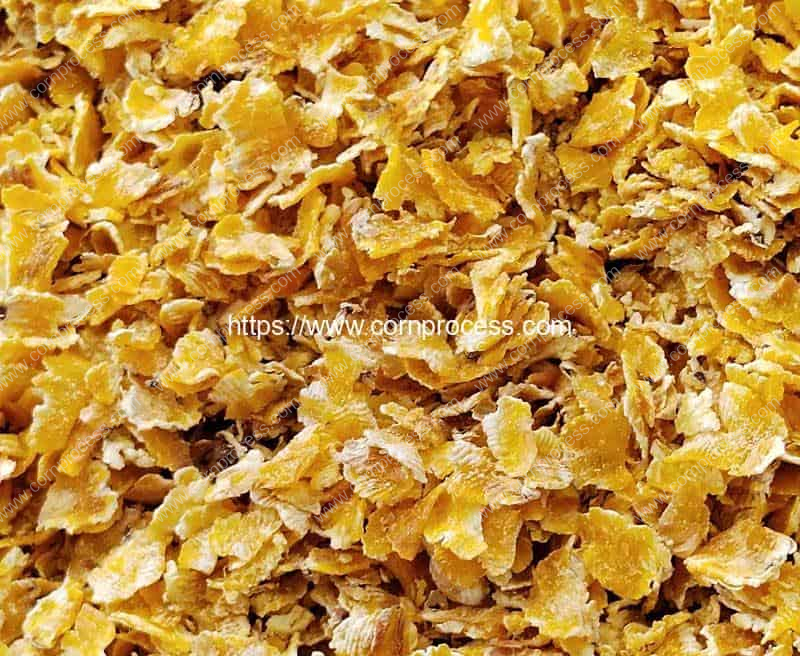

steam flaking corn feed production line( also called as steam flaked corn feed production line or steam corn flake feed production line) is used to make steam flaked corn for animal feed. Steam-flaked corn (SFC) is commonly fed in feedlot finishing diets because steam flaking improves starch availability and nutrient utilization, thus improving the overall feeding value of corn (Zinn et al., 2002). In most operations that use SFC, grain is processed to a predetermined flake density by setting the rolls to a specific separation distance and using tension to hold rolls together. Flaked grain is generally produced to a bulk density between 0.31 kg/L (24 lb/ bu) and 0.41 kg/L (32 lb/bu; Owens et al., 1997), with an average recommendation of 0.35 kg/L (27 lb/bu) for corn (Vasconcelos and Galyean, 2007); however, flake density among steam flakers within a single mill and among feedlots can vary greatly. Flaking to a similar density using 2 flakers does not ensure similar starch availability (Armbruster, 2006).

The degree of starch gelatinization or starch availability of SFC can be estimated using analytical procedures such as enzymatic hydrolysis, gas production, and SFC gelatinization methods (Vasconcelos and Galyean, 2007). Routinely evaluating starch availability is used as a quality control method to standardize the steam-flaking process to ensure within-day and day-to-day manufacturing consistency. The concentration of readily available starch in SFC is indicative of the rate of starch fermentation in the rumen. When starch is too readily available and is fermented at an excessively rapid rate, acid can accumulate in the rumen, reducing ruminal pH, and ultimately resulting in increased prevalence of digestive disturbances.

Factors that contribute to variation between feedlot operations with respect to SFC quality include type and dimensions of flaking equipment, grain type, grain variety and moisture content, roll wear, and steam-flaking procedures. Sampling and handling procedures contribute to precision of results; therefore, sampling procedures need special attention, and consistency must be evaluated when attempting to determine starch availability of SFC.

The objectives of this study were to evaluate starch availability of SFC comparing roll dimensions and SFC flake densities among flaking systems, to provide information on equipment used and SFC flaking procedures, and to define current manufacturing practices of steam flaking in commercial feedlot operations.

Structure of Steam Flaked Corn Feeding Production

Workshop Dimension of Steam Flaked Corn Feed Making Machine

Working Video of Steam Flaked Corn Feed Production Line

Company Profile

Romiter Machinery Co., Ltd. is a market-leading designer and manufacturer of corn processing machines. Romiter Machinery wins a wide reputation for high-quality machines with high efficiency, excellent reliability, easy maintenance, long lifespan and an excellent technical support team.

Now, Our factory can provide corn washing cleaning machines, corn dehusking machines, corn threader machines, corn cutting machines, popcorn making machines, kettle corn making machine, corn flakes making machines, steam flaked corn production line, corn packing machine, vacuum packed fresh corn production line, frozen sween corn kernel production line. corn flour milling machine, and corn grits milling machine

Romiter Group can provide customized machine for customers. Welcome to contact us for more information.